Low-temperature drying effect of sludge in chemical industry

● Project Introduction

Electroplating wastewater treatment system, using plate and frame filter press for dehydration, daily output of 1 to 2 tons of wet mud containing heavy metals, stable output of 1.5 tons, mud cake moisture content of about 70%, according to common sense, wet mud reaches this index It is already very good, but there is still a problem, what's the matter?

一.One, the workers are suffering

One or two tons of mud is not too much, and there is not much work. However, it is dirty and smelly. This is not the most important. It is corrosive. Although the sewage has undergone layer-by-layer conditioning, the platform steel frame on the site has corroded, and I am afraid to look at it.

The green mud cake, the cross-flowing sewage, the corroded steel frame, how can you not be happy to deal with these every day? Wanting to say hello to the little girl at the front desk, the old man walked away with his nose covered.Second, the boss: Asking Jun how much can you worry, just like a river of spring flowing eastwardOn the one hand, the requirements of the processing unit are getting higher and higher, the processing pressure is getting less and less, the price is getting higher, and you have to rush to sign the contract, otherwise the quota will be gone; I have sorted out how many times I want to reduce the amount of sludge by improving the process, but the production capacity is increased, and the amount of sludge is still steadily rising. It is really worrying.

There is no way, I can only find foreign aid. I heard that the heat pump low-temperature drying investment is low, the effect is good, the technology is clever, it is simply perfect, and the investigation circle is finally finalized to cooperate with us.

● Project requirements

Ask for it, the site is like this, there is really no place, the platform can't move, and production is needed. The mud will be reduced by at least half, and the water content will be below 30%. There will be one more extension behind the platform. Just do it.

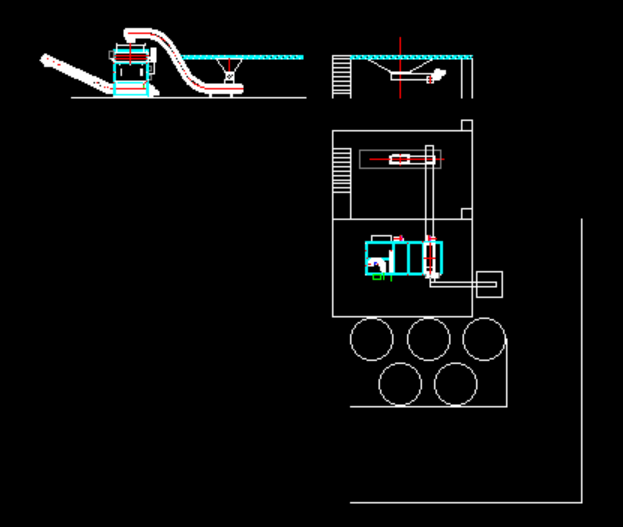

● Project Design

After detailed site surveys, communication surveys, consideration of future installation routes, discharge locations, operation and maintenance, expansion interfaces, etc., the entire project process has the following processes, which are indispensable.

●Process Description

(1) Mud cake crushing: Mud cakes so dehydrated by plates and dehydration are all large and large pieces, which are larger than Xinjiang cakes. They should be dried in a dryer, not broken, and digested slowly. Well, the crusher must be on;

(2) Wet mud lift: The old rust platform has just reached Yao Ming ’s shoulders, and it is just right to pick up a small cart at the mud cake outlet. If you want to enter the dryer, it must be higher than half of Yao Ming ’s head. Go up

(3) Wet mud feeding: finally feed, don't worry, you need to cut the strips and spread them evenly. This is the same as chewing and swallowing. The dryer also has a digestive system;

(4) Low temperature drying: digestion and absorption in the belly of the drying machine, and the residue is discharged from the body;

(5) Dry mud discharge: The residue of wet mud is dry mud, but at this time it is not waste, but baby, because useful resources can be extracted, all the points that are not falling are output through a set of conveyors;

(6) Dry mud bagging: Since it is a baby, use the cornucopia and put away the treasurebag.· Condensate treatment and odor treatmentSome people say that there is odor emission, it is impossible, the dryer is like a pixiu, and those who are lucky to enter the treasure, there is no exhaust port, how can there be odor emissions;Sewage Disposal? Nothing, I have done a distillation purification of the sludge water, it will not be dirty. Even if you ca n’t drink it, it ’s definitely cleaner than dehydrator water, so do n’t worry about discharging it back to the sink.

●Equipment selection

|

Serial number |

Project |

Parameter |

Remarks |

|

1 |

Processing capacity(t) |

1.5(70%) |

|

|

2 |

Dry mud(t) |

0.64(30%) |

|

|

3 |

Dewatering(t) |

0.86 |

|

|

4 |

Processing time(h) |

24內(nèi) |

|

|

5 |

Low temperature dryer model |

JCD1200SL |

|

Whether it is Yipingpingchuan, or horns, I will do my best to meet your needs

● Benefit Analysis

|

Model |

Rated power(kw) |

Operation hours(h) |

Sludge treatment capacity(T) |

|

JCD1200SL |

15 |

18 |

1.5(70%) |

|

Dry mud output(T) |

Auxiliary equipment rated power(kw) |

Water price(yuan/t) |

Electricity price(yuan/degree) |

|

0.64(30%) |

≈10.4 |

4 |

0.7 |

Low-temperature drying cost: due to the actual operating characteristics of the system, the system energy consumption is calculated as 3kg.H2O / kw.h, the project water removal 1.5-0.64 = 0.86 tons / day, power consumption 860 ÷ 3 = 286.67kw.h, total electricity It is 286.67 × 0.7 = 200.67 yuan, water fee 0.5 × 18 = 9 tons, the total water fee is 4 × 9 = 36 yuan, a total of 236.67 yuan.

Disposal cost after reduction: dry mud output 0.64 tons, disposal cost 0.64 × 1500 = 960 yuan, total disposal cost 960 + 236.67 = 1196.67 yuan.

In summary: after the reduction, the daily sludge disposal cost can be saved 2250-1196.67 = 1053.33 yuan.