Date:2020-03-05 Views:2844

Background: According to data released by the Ministry of Housing and Urban-Rural Development, as of the end of September 2016, a total of 3,976 urban sewage treatment plants have been built nationwide, with a sewage treatment capacity of 170 million m3 / d. Calculated based on 5 ~ 8t of sludge produced per 10,000m3 of domestic sewage (calculated at 80% moisture content), the current annual output of sludge in China exceeds 40 million tons, with a growth rate of 10% per year. It is estimated that between 2020 and 2025, China The annual output of sludge will exceed 60 million tons (calculated based on 80% moisture content).

Sludge drying As the problem of "sludge siege" has become more prominent and the country has paid more attention to environmental protection, the reduction, stabilization, and harmless treatment of urban sludge have been put on the agenda, and sludge treatment has become Focus of attention. Sludge drying can reduce the moisture content of the sludge, stabilize the remaining material, and greatly remove the malodor and pathogenic organisms. The sludge volume is reduced, while the heating value is increased, and the nutrients are retained. It can be used as granular fertilizer, and can also be further incinerated and land improvement. Its heating value can be used as an alternative energy source. Therefore, sludge drying is the premise and key of sludge treatment and disposal technology. Among the various technologies for sludge drying treatment, the low-temperature drying process can not only achieve sludge volume reduction and volume reduction with high efficiency, but also has a high safety operation coefficient, and is gradually widely used in municipal and industrial fields.

The largest sludge low temperature drying monomer project in China

Jialida Centralized Sludge Disposal Center, located in Datang Industrial Park, Sanshui District, Foshan, Guangdong, undertakes the task of treating sewage sludge discharged from the daily production and living of the surrounding industrial printing and dyeing parks and residential areas. With the economic development, the current sludge disposal capacity can no longer meet the needs of domestic sludge and printing and dyeing sludge disposal in Foshan.

In view of this, Foshan Jialida Environmental Protection Technology Co., Ltd. plans to choose the site of the first demonstration project of comprehensive utilization of sludge resources in Sanshui District, Foshan City, on the first plot of No. 67, Block A, Datang Park, Sanshui Industrial Park, Foshan City. The sludge centralized treatment center in Sanshui District, Foshan City will be rebuilt and expanded.

Construct a new sludge temporary storage room and drying workshop in Block 1 of Block A, Datang Park, Sanshui Industrial Park, Foshan City, to optimize the original sludge drying process in an all-round way, and adopt a leading low-temperature drying equipment system The original sludge drying equipment will be used as a backup after the reconstruction and expansion project is put into operation. After the expansion and expansion, the centralized sludge treatment center in Sanshui District, Foshan City intends to collect, store, and treat printing and dyeing wastewater treatment sludge and sewage treatment sludge generated from urban centralized domestic sewage treatment plants. The scale will be increased to 1,000 tons / day (water content 80 %), After drying at low temperature to 25% moisture content, it will be sent to Foshan Jialida Environmental Technology Co., Ltd. Thermal Power Plant for blending with thermal coal.

Location of Foshan Jialida Sludge Centralized Disposal Center 1. Project Name: Foshan Sanshui District Sludge Centralized Disposal Center Construction Project 2. Construction Unit: Foshan Jialida Environmental Protection Technology Co., Ltd. 3. Construction Location: Foshan Jialida Environmental Technology Co., Ltd. Thermal Power Plant, Datang Park, Sanshui Industrial Zone, Foshan City, Geographical coordinates: N23 ° 26'39.34 ", E112 ° 56'7.44" 4. Construction content: storage and transportation of sludge Systems, drying and electric coal blending systems, exhaust gas purification and treatment, electrical automatic control instrumentation systems and auxiliary systems, etc. 5. Treatment scale: Collecting, storing, and treating printing and dyeing wastewater treatment sludge and sewage treatment sludge produced by urban centralized domestic sewage treatment plants totaling 1,000 tons / day (80% water content). 6. Treatment process: The wet sludge (80% moisture content) is dried and dried to 25% moisture content and then mixed with the electric coal according to the set blending ratio and sent to the boiler of Jialida Thermal Power Plant for incineration.

Steam absorption heat pump belt dryer

Engineering unit 1. Main project: Drying workshop, a production workshop at Block 67, Datang Park A, Sanshui Industrial Park, Foshan City. A new drying workshop was set up on the 3rd and 4th floors. A batch of drying equipment was updated. In order to save energy and protect the low temperature drying process, the wet sludge (80% moisture content) is dried to dry sludge (25% moisture content). The original drying workshop and drying equipment are reserved. 2. Storage and Transportation Project: Wet sludge temporary storage room, a new wet sludge temporary storage room is set up on the first floor of the first floor of the first workshop of Block No. 67, Block A, Datang Park, Sanshui Industrial Park, Foshan City. Device. The original wet sludge temporary storage room is reserved. 3. Dry sludge tank: A dry sludge storage tank is newly built on the first floor of the first floor of the first workshop in Block A, No. 67, Block A, Datang Park, Sanshui Industrial Park, Foshan City, and sealed. Raw dry sludge tanks are reserved. 4. Sludge Conveying System: A three-dimensional sludge conveying system is constructed in the first to third floors of the first workshop in Block 67, Block A, Datang Park, Sanshui Industrial Park, Foshan City, including bucket elevator, screw conveyor, feeding Machines, etc., are fully enclosed. The original sludge transportation system is used as a backup. 5. Relying project: The coal blending of Jialida Thermal Power Plant will not change, and the dry sludge and coal will be mixed in a certain proportion and sent to the boiler of Jialida Thermal Power Plant for incineration.

Sludge drying is the first step in the utilization of resources. Energy-saving sludge low-temperature drying equipment breaks the isolation of industry technology and becomes the key to the front-end dewatering + low-temperature dehumidification drying + incineration and other sludge chain processing technologies. System to realize closed-loop connection of sludge treatment and disposal technology.

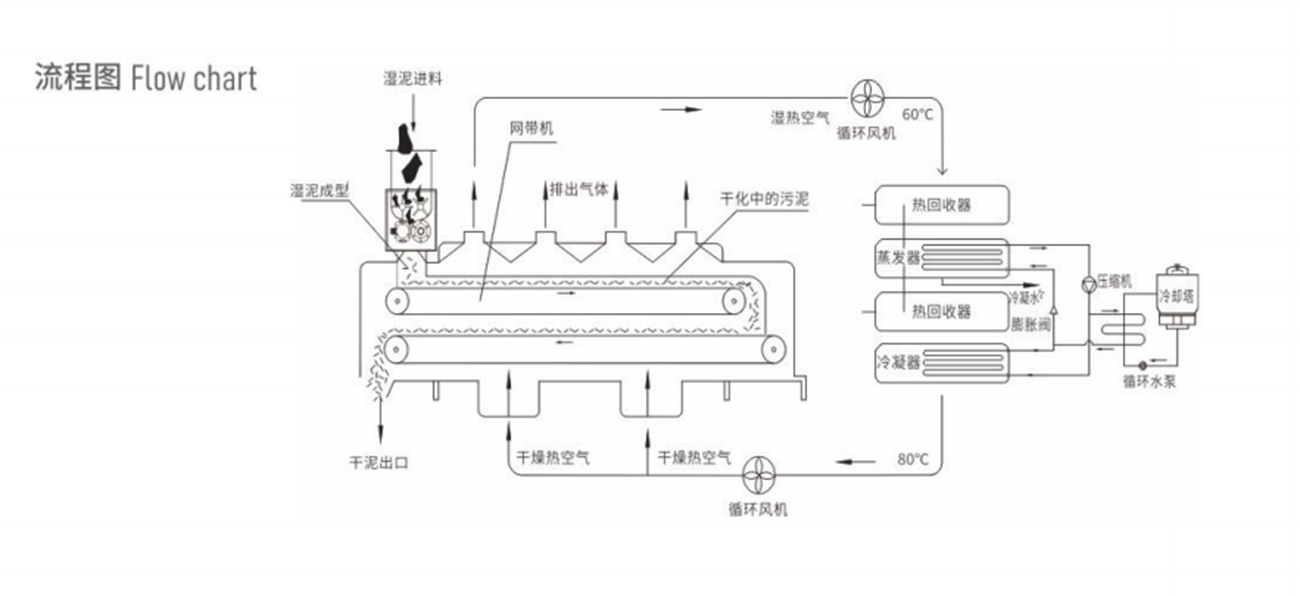

"Front-end dehydration + low-temperature condensation drying" combined technical solution not only improves dehydration efficiency, but also saves operating costs. The regenerative circulating mesh belt drying belt sludge dryer uses the continuous circulating drying air to take away the sludge moisture on the mesh belt in the drying tunnel, so that the volume and weight of the sludge can be reduced, and the filter belt, centrifugation, and plate can be processed. The sludge from the dewatering machine such as the frame, the dewatered sludge is distributed on the ventilated mesh belt, and the mesh belt is slowly forwarded in the drying tunnel, and the circulating dry air evaporates the sludge moisture. The entire drying process is performed in a sealed environment, and no odorous dust will escape.

Low temperature drying (80 ℃) can fully avoid the volatilization of different types of organic substances in the sludge and the volatilization of malodorous gases (the temperature of volatilization of chain alkanes and aromatic hydrocarbons is 100-300 ℃; the volatilization temperature of naphthenes is mainly at 250-300 ℃; the volatilization temperature of nitrogen-containing compounds, amines and oximes is mainly 200-300 ℃; the volatilization temperature of alcohols, ethers, fatty ketones, amide nitriles, etc. are all above 300 ℃. (The volatilization temperature of aldehydes and anilines is mainly at 150 ° C, and the volatilization temperature of lipids is at 150-250 ° C)

Odor emission: working at low temperature below 80 ℃, little non-condensable VOC gas, simple odor treatment.

Steam absorption heat pump low temperature belt drying system

Through the absorption heat pump, the heat of the cooling circulating water in the dryer is recovered as a heat source, and the heat circulating water is released to the dryer, not only can the heat of the cooling water (42 ° C) be used to heat the dryer. The internal thermal circulating water (70 ℃), and then using the heat source steam, reheat the thermal circulating water to 90 ℃, and use it as the heat source of the dryer, thereby greatly reducing the steam consumption of the equipment and further improving the energy efficiency of the drying equipment.

Dust and temperature control The traditional thermal drying technology route uses high temperature dried sludge of 150-200 degrees. During the drying process of sludge, it is easy to generate dust when the temperature is higher than 80 ° C. In particular, it is necessary to control the dust concentration. When it is greater than 60g / m3, Danger of dust explosion. Solution: The sludge is placed statically, there is no mechanical static friction with the contact surface, and there is no "sticky phase" stage. The dust concentration during drying can be controlled <60mg / m3, and there is no danger of dust explosion;

The discharge temperature is low (<50 ℃), no cooling is required, and it can be directly stored or packed in tons.

Efficient and resource-efficient can directly dry the sludge with 83% moisture content to 10%, without the need for staged disposal (such as plate and frame filter press + thermal drying, thin layer drying + belt drying, etc.);

There is no loss of organic matter in the drying process, and the dry material has a high calorific value, which is suitable for the later use of resources; the capacity reduction can reach 67% and the weight can reach 80%, which can save a lot of later transportation costs and can be suitable for 83% -50% water content pollution Mud drying

Condensate wastewater discharged up to standard The effluent wastewater of this project is mainly dried condensate wastewater, which mainly contains sulfide and other pollutants, and is discharged to the Datang Sewage Treatment Plant for treatment. After treatment by the Datang Sewage Treatment Plant, it reached the first-stage standard in the second period of DB44 / 26-2001 and GB4287-2012 and its amendment (Ministry of Environmental Protection of the People's Republic of China Announcement 2015 No. 41, that is, the suspension of the implementation of GB4287-2012 The aniline and hexavalent chromium emission control requirements in Tables 2 and 3, and the strict requirements for the aniline and hexavalent chromium implementation requirements in Table 1 during the suspension period, meet the standards.

Dry mud storage tank and transportation

The sludge with a moisture content of 25% is weighed by a dry mud tank bottom belt scale, and then sealed and transported to the coal hopper, mixed in proportion and sent to the boiler of Jialida Thermal Power Plant for incineration.

Generally, the sludge will be sent to the coal hopper for mixing after drying. However, when the sludge supply exceeds demand, dry sludge will be temporarily stored in the dry sludge storage tank at this time, and several sludge storage tanks are full, and they need to be discharged through the discharge belt in the dry sludge temporary storage room. Then, the sludge is sent to the coal hopper by a coal-traveling vehicle with a height of about 5 meters.

The sludge transmission of other supporting facilities reconstruction and expansion projects adopts closed transmission devices, and the lifting points, conveyors, and blanking points between all equipment are closed. In order to prevent dust accumulation in the closed transmission equipment, a ventilation system is set up to exhaust the dust-containing gas in the equipment and send it to the biological deodorizing spray tower for treatment and discharge. Exhaust gas treatment: In order to prevent dust accumulation in the closed transmission equipment, a ventilation system is set up to exhaust the dust-containing gas in the equipment and send it to the biological deodorizing spray tower for treatment and discharge. The waste gas produced by the mixed combustion of dry sludge and electric coal is treated by the boiler waste gas treatment system of Jialida Thermal Power Plant. Solid waste treatment: slag and fly ash produced by the mixed combustion of dry sludge and electric coal, and coal slag and coal ash produced by the self-combustion of electric coal, temporarily stored in the slag and ash warehouses of Jialida Thermal Power Plant use. Public and auxiliary facilities: The steam used in the drying plant is provided by Jialida Thermal Power Plant, and the steam condensate produced is used as the make-up water for the boiler of Jialida Thermal Power Plant. Other public and auxiliary facilities such as water, electricity and firefighting rely on the public and auxiliary system of Jialida Thermal Power Plant.

After the implementation effect of the project was expanded, the scale of the sludge centralized treatment center in Sanshui District, Foshan City collected, stored, and treated the printing and dyeing wastewater treatment sludge and the sewage treatment sludge produced by the urban centralized domestic sewage treatment plant increased to 1,000 tons / day Rate 80%), after drying at low temperature to 25% moisture content, it will be sent to Foshan Jialida Environmental Technology Co., Ltd. thermal power plant for blending with thermal coal to achieve sludge reduction, harmlessness and resource utilization. Disposal and utilization.