Date:2020-03-06 Views:2957

Summary

Mechanical dewatering of sludge is an important part of sludge reduction. The key lies in the selection of sludge conditioning methods and the selection of dehydrators. There are four problems in the current choice of chemical conditioning and sludge mechanical dewatering models:

The first is the selection of chemical conditioning agents;

2 definitions and measurement methods

In addition, the sludge filtration time (TTF) can also better characterize the sludge dehydration. It refers to the filtration time required when the volume of the filtrate reaches half of the volume of the sludge. Relevance.

The specific resistance of most sludges and capillary water absorption time also have a good correlation, and the regularity of the dehydration performance changes can often be consistent.

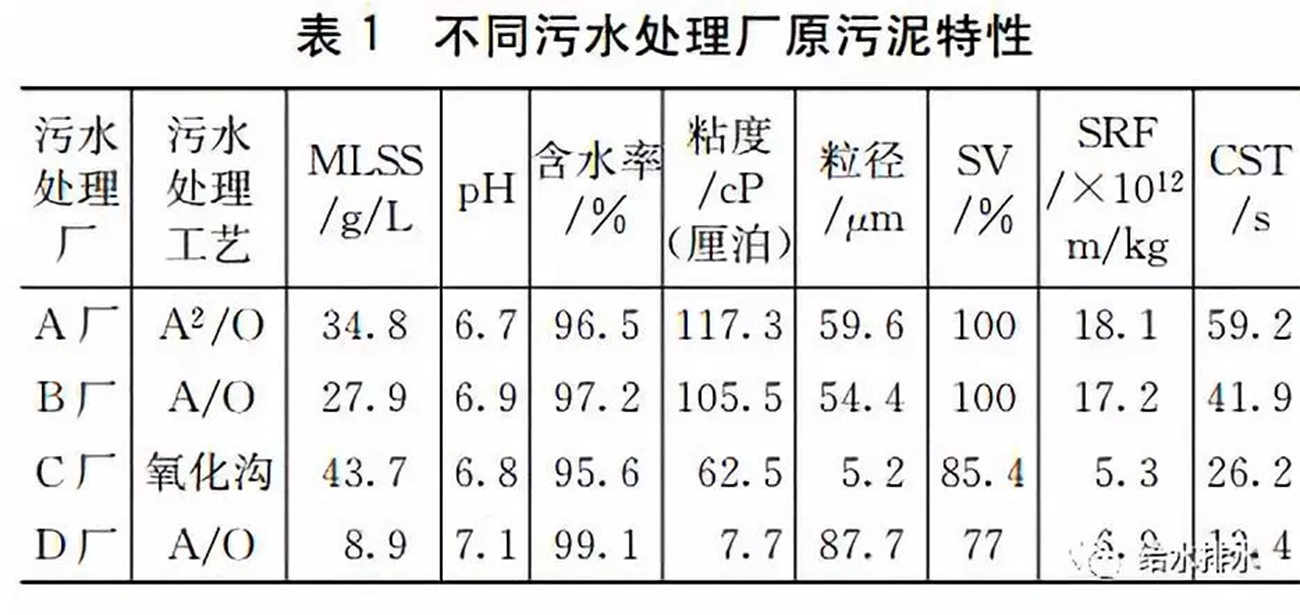

3 materials and methods

3.2 Determination test of sludge dewatering performance

After chemical conditioning, the sludge formed floc, and the water layer of the mud was obvious and in a heterogeneous state, which greatly affected the measurement of specific resistance and capillary water time. Therefore, this paper proposes a method for measuring the sludge at high speed after conditioning, and performs correlation analysis between specific resistance, filtration time, capillary water absorption time, and particle size indicators under both agitated and non-stirred conditions to determine the method's Effectiveness and reliability. The test proves that the data after adding the conditioning sludge to the stirred pretreatment is more reliable and more accurate.

After taking 400 mL of the remaining sludge or concentrated sludge sample from a sewage treatment plant and mixing it in a container, add different types or different amounts of PAM and stir with a six-link mixer. The conditioning conditions were: stirring at 200 r / min for 30 s, and then stirring at 60 r / min for 10 min. After standing for 10 minutes, the sludge was stirred at 500 r / min for 2 minutes using a high-speed mixer, and then the specific resistance, capillary water absorption time and particle size of the sludge were determined.

3.3 Analysis method

MLSS and moisture content were measured using national standard methods.

The pH was measured using a HQ30d multi-parameter tester (Hach, USA). Sludge specific resistance was determined by the method reported by Zhang Feijuan and Xu Jingcheng. TTF can be obtained during the specific resistance measurement process. CST was measured using a 304M tester (Triton, USA). The particle size was measured using a SALD-2201 laser diffraction particle size distribution analyzer (Shimadzu, Japan). Sludge viscosity was measured using a DV-I Rotary Viscometer (Brookfield, USA). Total organic carbon (TOC) was determined using Multi N / C3100 (Analytikjena, Germany).

4 Results analysis and discussion

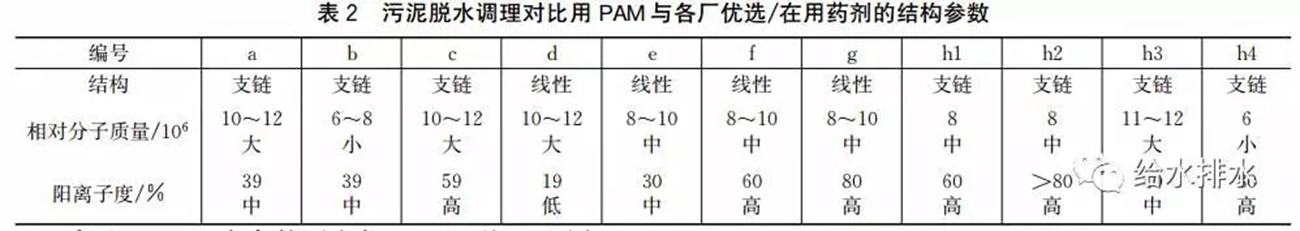

4.1 Analysis of the influence of conditioning agent types

Seven different polyacrylamide PAM agents (a to g in Table 2) with different structures, relative molecular weights and cationicity were selected in the experiment to study the effect on the dewatering performance of sludge. Based on the comparison of the pharmaceutical parameters, the pharmaceuticals strong, strong, h3 and h4 currently used in each plant were compared.

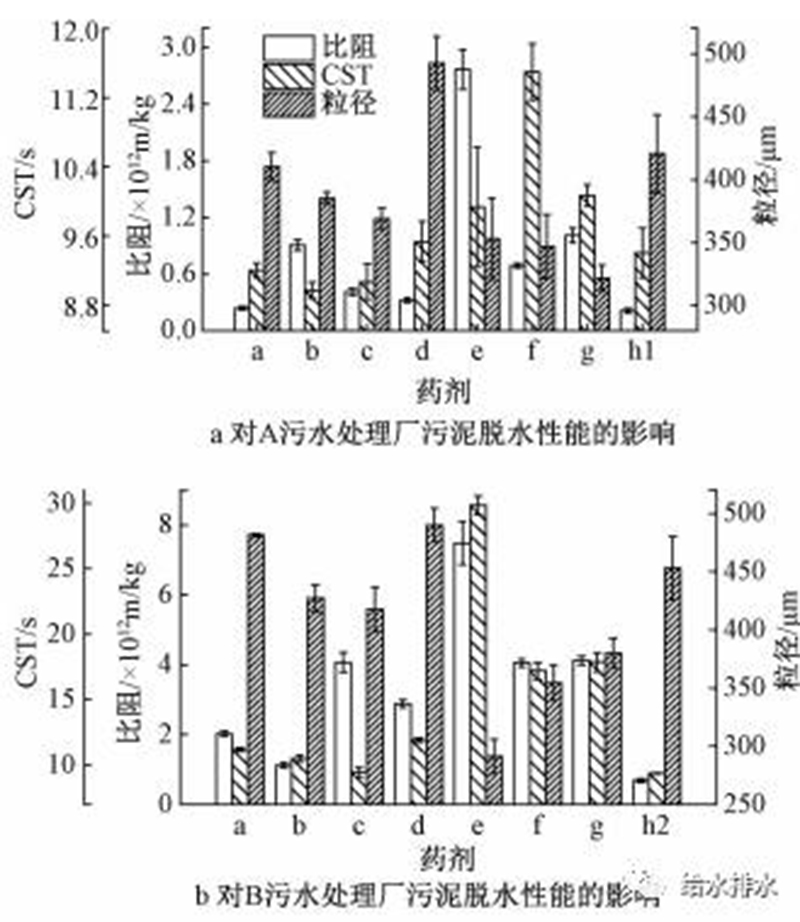

Figure 1 shows the changes in sludge dewatering performance after conditioning.

The change of sludge dewatering performance index after conditioning various chemicals in sewage treatment plant is shown in Figure 1a. The sludge after conditioning with large relative molecular weight branched chain agents a, c and linear agent d is significantly smaller than the small molecular weight branched chain agents b, and smaller than the medium relative molecular weight linear agents e, f, and g. After the small relative molecular weight branched chain agent b is conditioned, the sludge has the smallest capillary water absorption time, and the branched chain agents a, b, and c have improved capillary water absorption time better than the linear agents d, e, f, and g. The particle size of the rear sludge increased significantly, among which the linear large molecular weight drug d was the most obvious; the cationic degree had no significant effect on the sludge dewatering performance index, but the linear low cationic drug e had the most significant effect on improving dewatering performance. difference. The plant currently uses a medium molecular weight branched chain agent strong. At the same dosage, the specific resistance of the sludge is the lowest among the contrast agents. The capillary water absorption time is higher than other comparative branched chain agents, and the particle size is suboptimal. . The plant currently uses a centrifugal dehydrator, which is measured in terms of capillary water absorption time, and it is recommended that medicament b be used.

The change of sludge dewatering performance index after conditioning various chemicals in sewage treatment plant is shown in Figure 1b. The specific resistance of the sludge after conditioning with the small relative molecular weight branched chain drug b is significantly smaller than that of the large relative molecular weight branched chain drug a, c and linear agents d, e, f, and g; the effect of branched chain drug on capillary water absorption time Significantly better than linear agents; high cationic branched chain agent c has poor improvement in contrast resistance; large relative molecular weight linear low cationic agent d improves contrast resistance and capillary water absorption time better than other linear agents; medium cationic linear agents The improvement effect of e contrast resistance and capillary water absorption time were the worst; except for e, the particle size of sludge was significantly increased after conditioning. At present, the plant uses a medium molecular weight branched high cationic agent strong. At the same dosage, it has the best improvement in specific resistance and capillary water absorption, and the particle size increases after conditioning. The plant uses The centrifugal dehydrator, based on the capillary water absorption time, is suitable to use the agent strong.

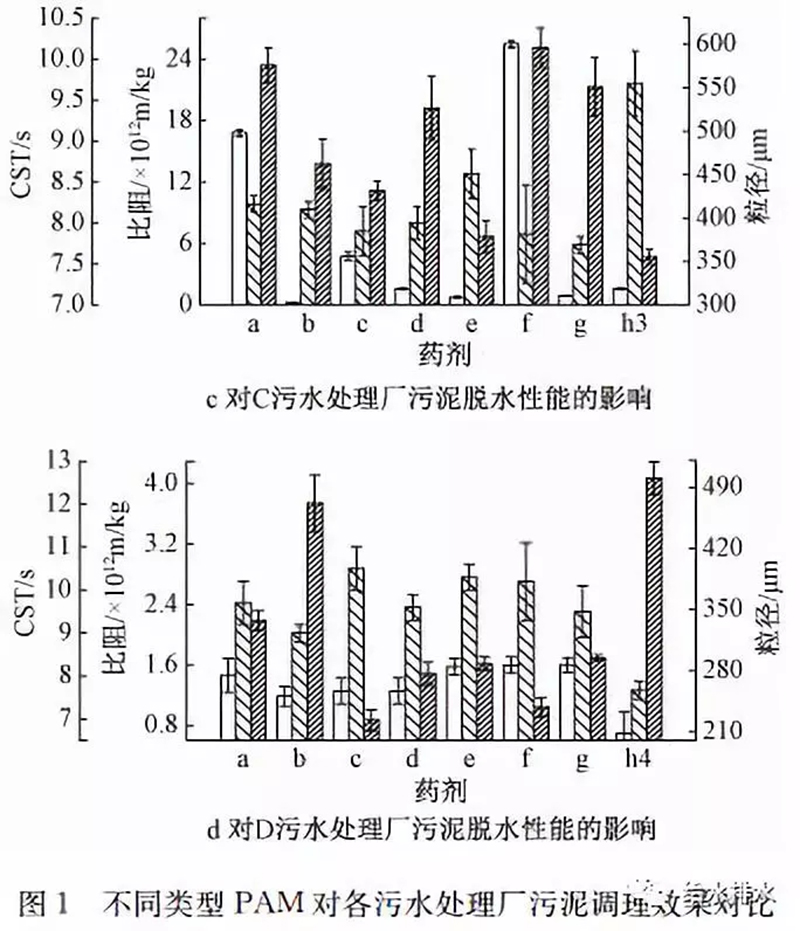

See Figure 1c for details of the sludge dewatering performance changes after various chemicals of the sewage treatment plant are conditioned. The specific resistance of the sludge prepared with the small relative molecular weight branched chain drug b is significantly smaller than that of the large relative molecular weight branched chain drug a, c. Except for the linear agent f, the other linear agents have better comparative resistance improvement effects. In comparison, The large relative molecular weight branched chain agent c and the medium relative molecular weight linear agent g have the best effect on improving capillary water absorption time, and the sludge particle size after the agent conditioning has also been significantly increased; the agent in the factory using agent h3 is a large relative molecule. The cationicity in the quality branch chain, the specific resistance of the sludge is lower after conditioning, but the capillary water absorption time is the highest in the contrast agent, and the sludge particle size is the smallest; the plant uses a belt dehydrator, which is measured in terms of specific resistance, and the relative molecular mass should be used. For cationic drugs, drug b is recommended.

D. The change of sludge dewatering performance index after conditioning various chemicals in sewage treatment plant is shown in Figure 1d. The improvement of the comparative resistance of the three branched-chain agents is close, and it is slightly better than that of the agent b; the improvement of the comparative resistance of the linear agent with a large molecular weight and a low cationic degree d; Better than other branched chain medicines; medium relative molecular weight high cationic linear agent f improves capillary water absorption time better than other linear agents; the factory currently uses a small relative molecular weight high cationic branched chain agent h4, at the same dosage , Its specific resistance and capillary water absorption time are better than other agents, and the sludge particle size is the highest; the plant uses a belt dehydrator, measured by specific resistance, so the plant currently using the agent h4 is suitable.

The above tests show that the existing sludge dewatering and sludge dewatering facilities before operation put into operation a targeted selection test of conditioning agents, which is of great significance for the selection of conditioning agents suitable for sludge properties and dehydrators.

4.2 Analysis of the influence of dosage of conditioning agents

Based on the drug selection test, the optimal dosage of the selected drug can be tested. This article analyzes the test results of the optimal dosage of the in-use agents in the four plants as follows, see Figure 2 for details.

A sewage treatment plant uses the agent strong, and the specific resistance of the sludge, capillary water absorption time and particle size changes after conditioning are shown in Figure 2a. The specific resistance and capillary water absorption time show an overall downward trend with the increase of the amount of PAM added, which decreases rapidly in the range of 0 to 2 kg PAM / tDS and then stabilizes. When the dosage was 4 ~ 5 kg PAM / tDS, the specific resistance of the sludge and the capillary water absorption time started to maintain at a low level, (0.21 ~ 0.23) × 1012 m / kg and 9.5 ~ 9.7 s, respectively. The dewatering performance is improved. The particle size showed an upward trend with the increase of the amount of PAM added, and tended to be unchanged after the amount of PAM / tDS was greater than 5 kg.

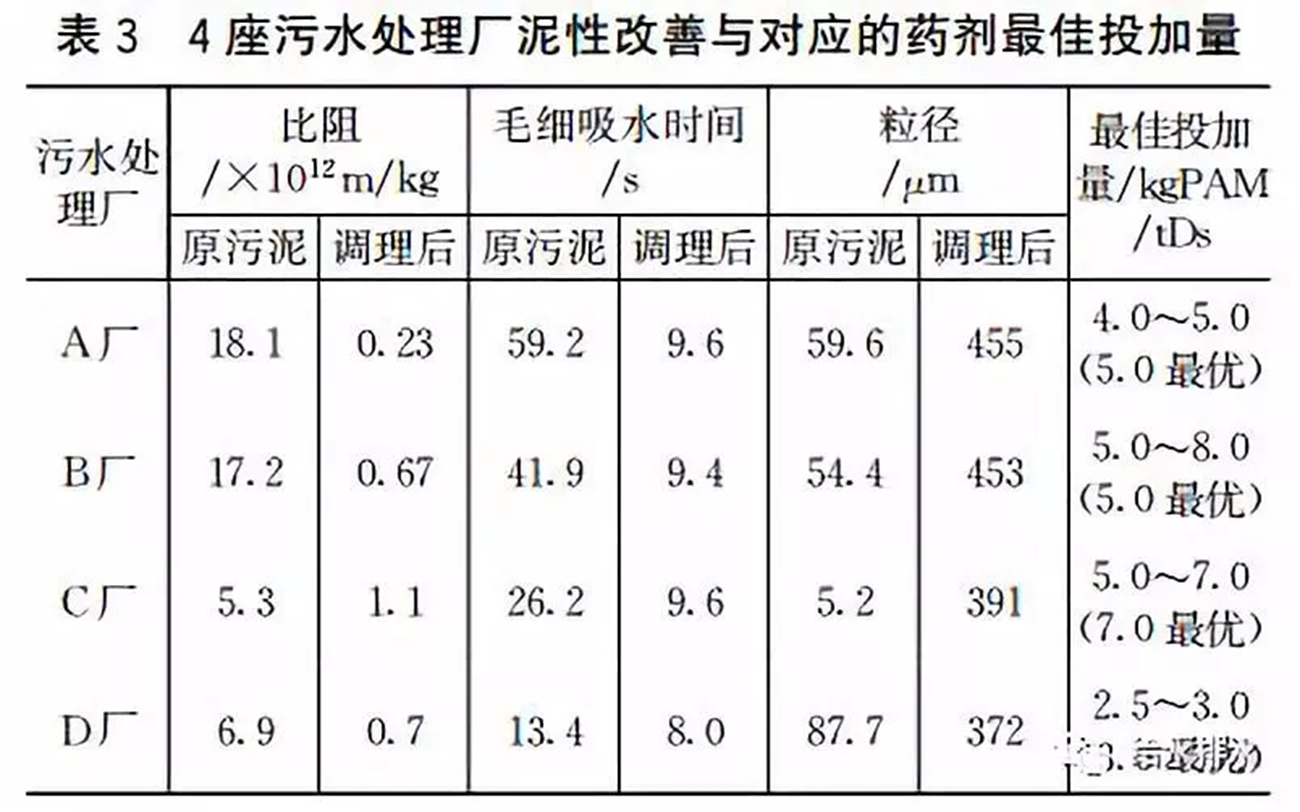

Except for the difference in the range and the range of change, the other plants adopted the specific resistance, capillary water absorption time, and particle size after conditioning with the agent, which corresponded to the optimal amount at a certain dosage. The increase situation is shown in Table 3.

The CST and particle size values tended to be stable at high PAM dosages, but the specific resistance of sludge increased. This is because part of the PAM remains in the supernatant of the conditioning sludge, which is enriched on the surface of the filter paper during filtration, which increases the filtering resistance. There is an error in the specific resistance measurement.

4.3 Analysis of the influence of mudiness on the choice of dehydrator

In addition to sludge conditioning methods, the key to sludge dewatering is the choice of dehydrator type. The selection of the dehydrator is also closely related to the muddy property and the improvement of muddy property after conditioning. From the working principle of belt dewatering machine, plate and frame filter press and centrifuge, sludge specific resistance and capillary water absorption time are the indicators to measure their selection.

Sludge specific resistance characterizes the resistance of water in sludge to pass through porous media under vacuum or pressure. The specific resistance measurement process includes two stages of filtration and pressure filtration, which is basically similar to the vacuum filtration dehydration process, so the specific resistance can accurately reflect the vacuum filtration dehydration performance of the sludge, and it can also accurately reflect the pressure filtration dehydration of the sludge Performance (such as belt dewatering machine and plate and frame dewatering machine). If the specific resistance of the sludge is better than the capillary water absorption time after conditioning, and it is less than 9.8 × 1012 m / kg, a belt dewatering machine or a plate and frame filter dewatering machine should be used. After the C and D sewage treatment plants are conditioned, their specific resistance is close to 1012 m / kg, so it is appropriate to use a belt dehydrator.

When the sludge is in contact with the filter paper, the time required for the water to penetrate the filter paper by 1 cm under the action of the capillary is called the capillary water absorption time. Therefore, CST can be regarded as the dehydration time, and it is measured in seconds [11]. Compared with SRF, CST can better reflect the performance of sludge centrifugal dewatering. If the CST of the treated sludge is better than that of SRF, and it is lower than 20 s, a centrifugal dehydrator should be used. After conditioning in Plant A and Plant B, the capillary water absorption time is less than 10 s. It is appropriate to use a centrifuge in both plants.

4.4 Discussion on Problems in Mud Property Analysis

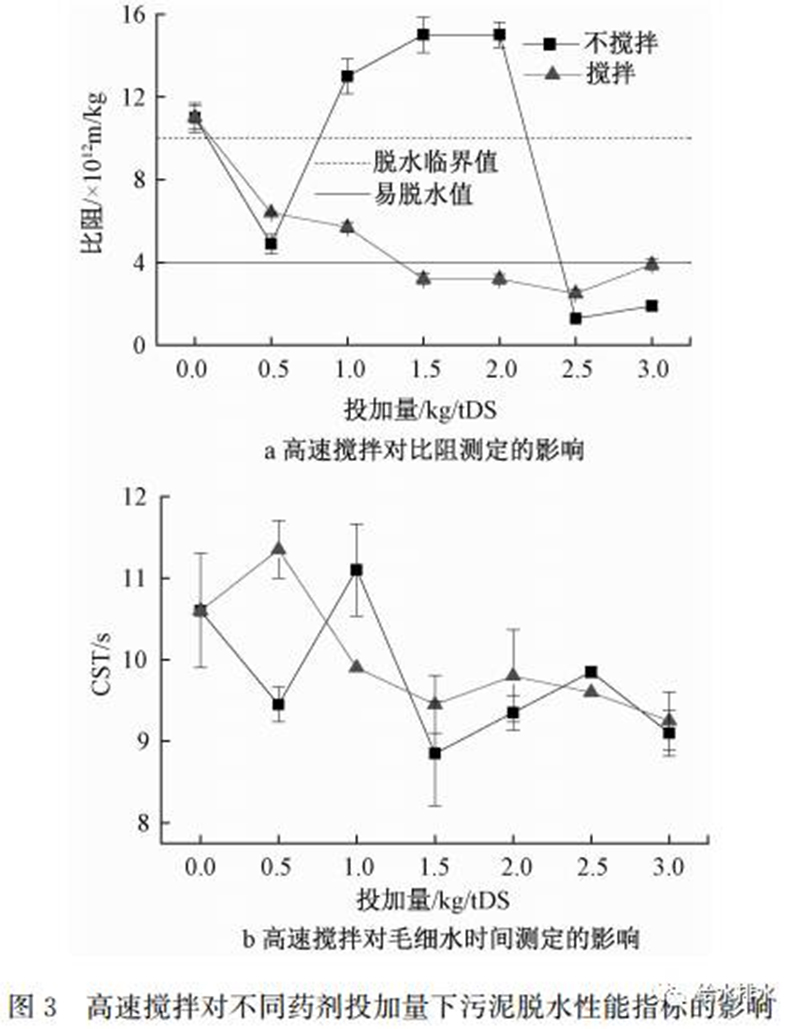

After the PAM conditioning, the sludge will form large irregular flocs, and the sludge water layer is fast and difficult to mix uniformly. This results in a large error in the measurement of the sludge of the conditioning sludge. Aiming at this problem, this paper presents a method for characterizing sludge after conditioning the sludge at high speed. After the sludge was conditioned, it was stirred at 500 r / min for 2 minutes at high speed to break up large-scale flocs and form a uniform sludge mixture. The effect of dosing and stirring on the dewatering performance of sludge is shown in Figure 3.

The specific resistance of the unstirred conditioning sludge rises first and then decreases with the increase of the dosage. In the range of 1 ~ 2 kg PAM / tDS, the specific resistance of the sludge is larger than the dehydration critical value (9.8 × 1012 m / kg), and then rapidly decreases. When the specific resistance of the sludge is greater than 2.5 kg PAM / tDS, the specific resistance of the sludge is smaller than the easy dehydration value of 3.9 × 1012. m / kg. The data fluctuates greatly, and the change trend does not match the actual law of sludge conditioning, indicating that the error in the characterization of sludge characteristics is large. After high-speed agitation, the specific resistance of the conditioning sludge showed a decreasing trend. When the dosage exceeded 1.5 kg PAM / tDS, it became stable, and the specific resistance value was less than the easy dehydration value, as shown in Figure 3a.

The unstirred CST value of the treated sludge fluctuated significantly, and the measurement error was large. However, the CST value of the treated sludge showed a decreasing trend after stirring, and the data fluctuation was small, as shown in Figure 3b.

The correlation analysis between sludge dehydration indexes before and after the stirring pretreatment is shown in Table 4. There was no significant correlation between the parameters of the unmixed conditioning sludge. After high-speed agitation, the correlations between sludge SRF, CST, and TTF and particle size during filtration were significantly increased. Sludge specific resistance, TTF, and particle size were significantly correlated at p <0.01. In addition, the unstirred adjusted sludge SRF has a positive correlation with particle size, which is inconsistent with the actual situation; and the stirred sludge SRF has a significantly negative correlation with particle size, which is in line with the actual situation. According to the above analysis, it can be known that the stirring pretreatment of the conditioning sludge can improve the reliability and accuracy of the measurement results.

CST is suitable for all sludge dewatering processes, but the moisture content of the sludge sample and the sludge to be dewatered is completely consistent, because the CST measurement result is greatly affected by the sludge moisture content.

Regarding the centrifugal dehydration process, recent studies have shown that compressibility and improved centrifugation index (MCI) are more promising indicators. In particular, MCI can quantify the pressure applied to the sludge surface during centrifugal dehydration, and then reflect the effect of dehydration equipment on the solid-liquid separation process performed. As a new muddy characterization indicator, MCI needs to further evaluate its reliability for sludge dewatering performance.

5 Conclusion

(1) Before determining the sludge conditioning agent and dosage, conducting a drug selection and corresponding optimal dosage test to improve the dehydration effect and reduce operating costs is undoubtedly beneficial, and can effectively avoid the selection and dosage of chemicals Determined blindness.

(2) The results of drug selection and optimal dosage test are undoubtedly beneficial to the selection of dehydration models, and can effectively avoid the blindness of design selection.

(3) The sludge measurement after high-speed agitating pretreatment of the sludge after the conditioning can more accurately reflect the actual law, and the reliability and accuracy of the measurement results are higher, which also shows that it is necessary to fully mix the chemicals and sludge during the conditioning process. .

(4) Chemical conditioning is an important pre-treatment process for sludge conditioning before dehydration. Its conditioning effectiveness directly affects the sludge dehydration efficiency. Therefore, the study of relevant sludge dewatering performance indicators and standardized measurement methods should be strengthened.